Industrielle Anlagenverlagerung

A successful plant relocation begins long before the first dismantling step.

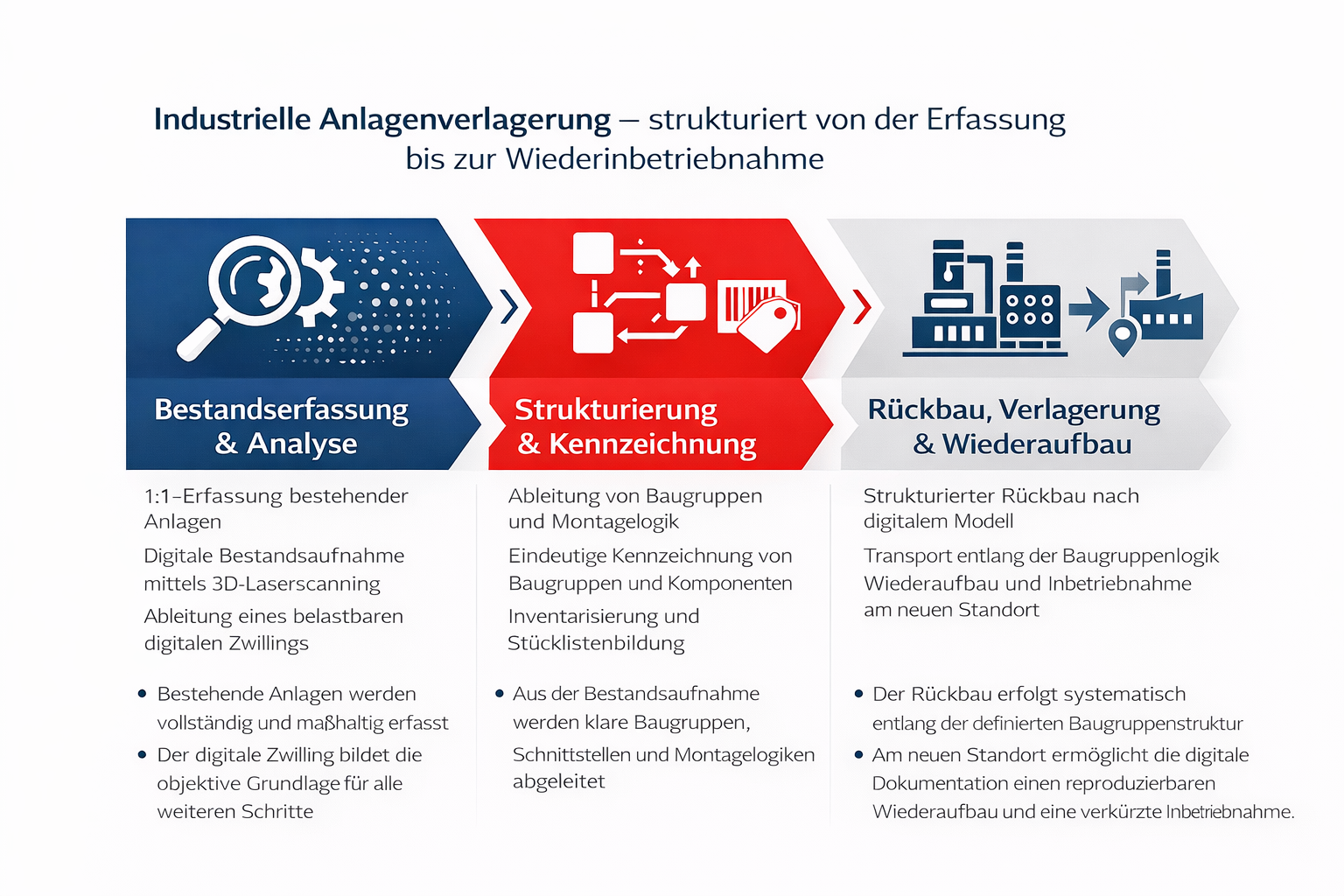

Through digital as-built documentation and clear structuring, dismantling, transport, and reassembly become predictable and controllable.

Dismantling, relocation, and reassembly using digital twin methodology

Industrial plant relocations are not merely a logistics task.

They are a technical challenge of analysis, structuring, and reconstruction.

Especially in long-established existing plants, reliable documentation, clear structures, and traceable assembly sequences are often missing.

The result is improvisation, time losses, and high downtime costs.

Our approach starts exactly here:

We capture existing plants 1:1, structure them systematically, and thereby create the foundation for controlled dismantling, safe transport, and reproducible reassembly.

Initial situation

Typical challenges in plant relocation projects:

- Incomplete or outdated as-built documentation

- Plants that have evolved and been modified repeatedly over the years

- Lack of clear assembly or modular structure

- Unclear allocation of utilities, media, and interface connections

- High dependency on individual personnel with experiential knowledge

Especially at larger industrial sites, this often leads to:

- Extended downtime periods

- Unplanned additional costs

- Conflicts between trades

- Delays in recommissioning

Our core principle

Complexity is not reduced – it is structured.

The methodology is independent of plant size.

Whether individual machines, production lines, or entire industrial sites – the approach always follows the same scheme.

Methodical approach

1. As-built capture (digital twin)

The process begins with a complete 1:1 capture of the existing plant using 3D laser scanning.

- Millimeter-accurate geometry

- Capture of machines, building structures, utilities, and foundations

- Registration into a consistent point cloud

- Supplementary photo and as-built documentation

Result:

A reliable digital twin serving as an objective basis for all subsequent steps.

2. Derivation of a structured plant model

From the digital twin, a technical model is derived that is not intended for visualization, but for dismantling and reassembly.

- Definition of machines and assemblies

- Assignment of interfaces

- Height, position, and reference definitions

- Assembly and disassembly logic

Goal:

To describe the plant in such a way that it can be reproducibly dismantled and reassembled.

3. Assembly logic & labeling

All relevant assemblies and components are systematically structured and clearly labeled.

- Clear hierarchy (Plant → Line → Machine → Assembly → Component)

- Unique identifiers

- Physical labeling on site (e.g., barcode / QR code)

- Assignment to the digital structure

Damit wird eine direkte Verbindung geschaffen zwischen:

- Physical component

- Digital model

- Assembly and transport logic

4. Inventory & documentation

Parallel to labeling, a structured inventory and bill of materials is created:

- Assembly and component description

- Dimensions, weights

- Utilities and connection information

- Special considerations for transport and assembly

These data are directly linked to the digital plant model.

5. Dismantling & transport

Dismantling is carried out in an assembly-oriented manner, not improvised.

- Clear disassembly sequence

- Transport-optimized assembly grouping

- Clear assignment during packaging and loading

- Reduced susceptibility to errors in logistics

Transport is thus based on a technical logic rather than on experiential assumptions.

6. Reassembly & commissioning

At the target site, reassembly is carried out consistently based on the prepared documentation:

- Clear position assignment

- Pre-prepared utility connections

- Traceable assembly sequence

- Reduced coordination issues between trades

The result is a shorter commissioning time and significantly higher planning reliability.

Scalability

The described approach is scalable.

The methodology remains the same –

only the scope, level of detail, and project duration vary.

- Individual machines

- Entire production lines

- Entire industrial sites

Classification

We do not view industrial plant relocations as a mere move,

but as an engineering-driven reproduction of existing systems at a new site.

This mindset creates structure – even in complex, long-established plants.