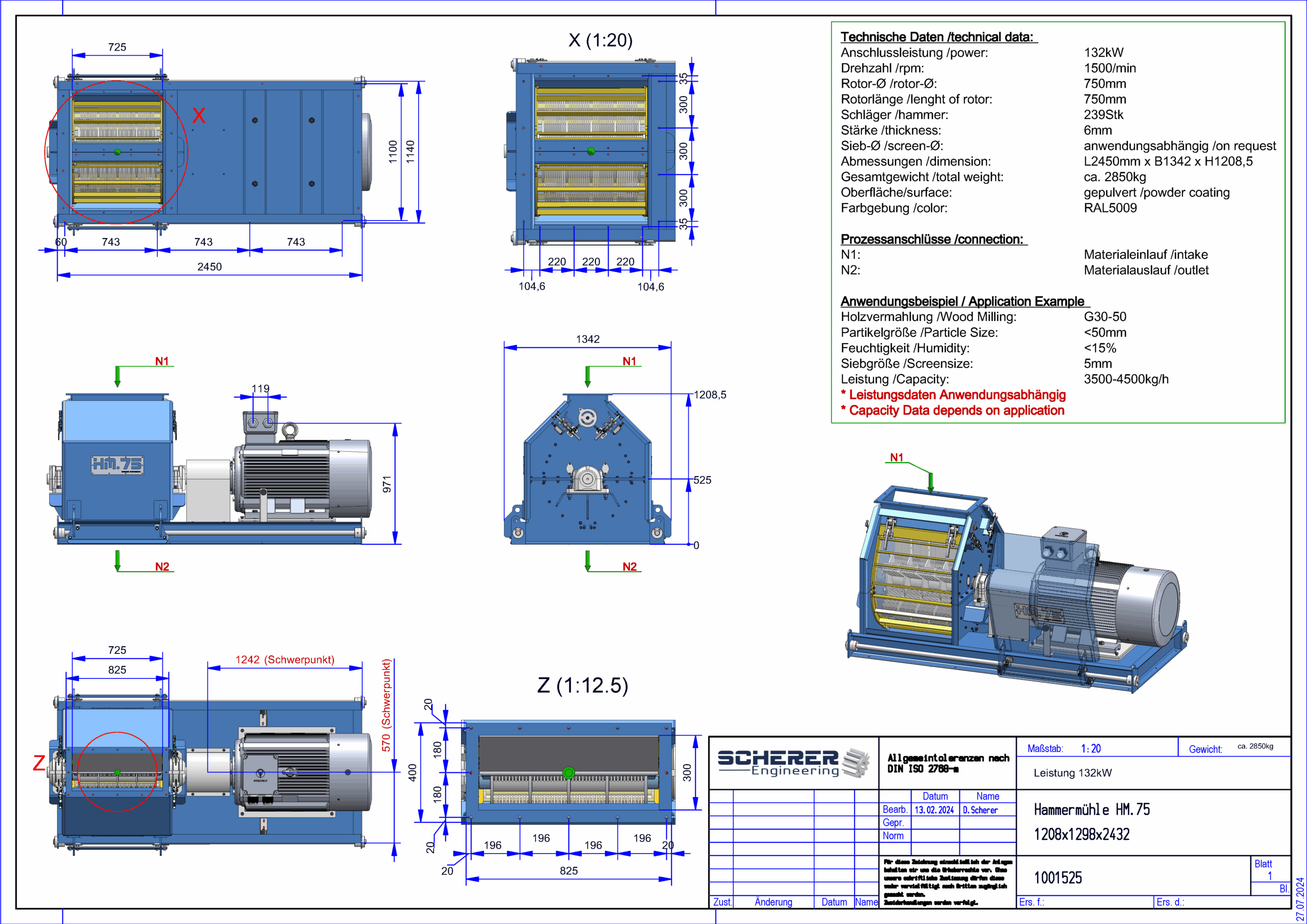

How the Scherer hammer mill came about – compact, easy to service and with intelligent direction of rotation control

The development of the Scherer hammer mill began with a fundamental question:

Why do hammer mills have to be so impractical when it comes to service, space requirements and wear?

Many plant operators work in confined spaces, in container systems or in halls with limited freedom of movement. Traditional hammer mills with swing doors made this unnecessarily complicated – and it was precisely this problem that was the starting point for a new design.

Swing doors: The underestimated space problem of classic grinders

Conventional grinders usually have hinged doors. This sounds practical, but in reality it is a considerable obstacle:

- The door requires additional space at the side to be able to open at all.

- The open door is in the way and blocks the work surface.

- Service work such as screen changes or inspections are made unnecessarily difficult.

This was simply not acceptable for compact systems.

The solution: Swing-out sliding doors – full accessibility without additional space requirements

The Scherer hammer mill relies on sliding doors that do not take up any additional space when opened.

Advantages:

- Ideal for tight spaces

- No door leaf blocking the working area

- Full access to rotor, portafilter and interior

- Ideal for container installations and row configurations

Service is not only becoming easier – it is finally becoming ergonomic.

Extremely quick screen change thanks to quick-release technology

Many market appliances use permanently welded portafilters, which slows down conversions.

The Scherer hammer grinder deliberately avoids this:

- Sieve carrier and sieves are separate

- Quick-release levers enable conversion in just a few minutes

- Different screen widths (3-10 mm and more) can be changed quickly

- No seized screws, no special tools

This makes the grinder ideal for companies with changing raw materials or quality requirements.

The rotor – robust, inexpensive and constructed from standard parts

Instead of a costly special rotor, a deliberately modular standard part rotor was developed:

- robust

- easy to maintain

- Low-priced spare parts

- High availability

- Low wear costs

This significantly reduces operating costs and simplifies maintenance considerably.

Intelligent rotation direction control – doubled beater service life without additional work

A special feature of the Scherer hammer mill is the adjustable inlet flap with mechanical position indicator.

It fulfills two functions:

- The flap position is immediately visible on the outside.

→ The operator can see the active operating position at a glance. - The control unit automatically recognizes the flap position.

→ The grinder can be operated either clockwise or counter-clockwise.

Why is this important?

Mallets wear out on the active striking edge.

With classic mills you have to:

- Stop the mill

- Remove the mallet

- turn around

- reinstall

… to use the second striking edge.

The Scherer hammer mill eliminates this entire process:

- Change direction of rotation

- New striking edge is used automatically

- A complete maintenance job is saved

- The service life of the mallets is significantly extended

This means:

- Less downtime

- Less working time

- Higher process stability

- Reduced costs

This function is one of the greatest practical advantages of the entire design.

Result

The Scherer hammer mill combined:

- Maximum accessibility through sliding doors

- Extremely fast screen changes

- Low wear and spare parts costs

- Intelligent direction of rotation control to extend the service life of the mallets

- Compact design for any system environment

- High robustness due to standard part design

It is a grinder that has been developed from practical experience – and optimized for practical use.