Technical due diligence of a used pelleting plant – independent assessment before investment decision

Initial situation

A customer was planning to purchase a used pelleting plant, preferably as a complete system, in order to reduce investment costs. As used systems are often difficult to assess on the market, a technical appraisal was required.

A supplier in Bosnia was found via second-hand exchanges who offered a pelleting line that was supposedly “only seven years old” – including drying, shredding, pressing, cooling and bagging. The description sounded promising, so an on-site inspection was arranged.

Insight on site

As soon as we arrived, the picture was completely different than expected:

- The machine was not seven years old,

but had only been used by the operator for seven years, but was assembled from older used machines. - The technical documentation was not provided.

- The maintenance status was unclear.

- Many system components did not meet European safety standards.

- The operating environment was very dirty, which made an assessment difficult.

Nevertheless, the system was basically functional – but under conditions that would not be permitted in the EU.

Carrying out the technical due diligence

The evaluation was carried out according to a structured scheme consisting of:

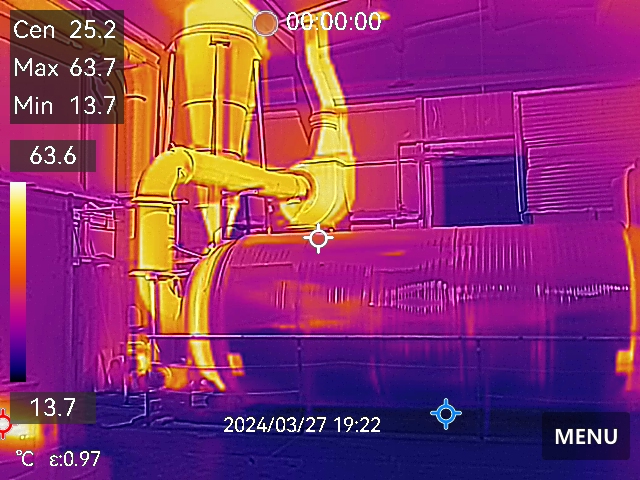

Analysis of the drying system

- Condition of the burner

- Air duct

- Safety devices

- Temperature behavior

- Energy efficiency

Evaluation of the shredding and conveying technology

- Mechanical condition

- Wear conditions

- Drive and storage technology

- Material flow

- constructive weak points

Examination of the pellet press and peripherals

- Roller/matrix state

- Press channel wear

- Gearbox and engine condition

- Vibration behavior

- Bearing and lubrication points

Cooling and bagging

- Throughput behavior

- Dust formation

- Ventilation conditions

- Condition of the transport routes

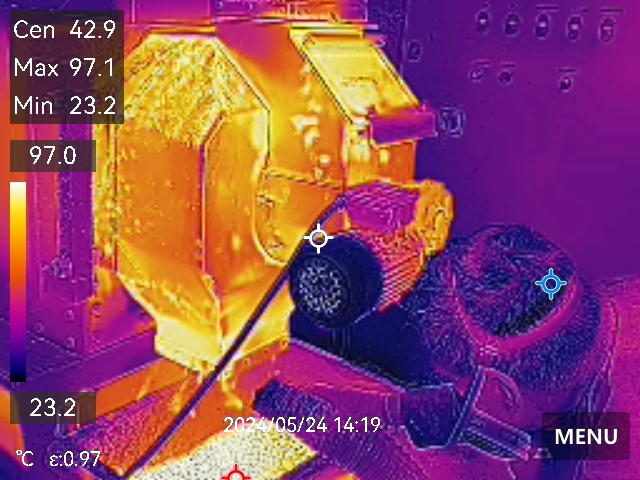

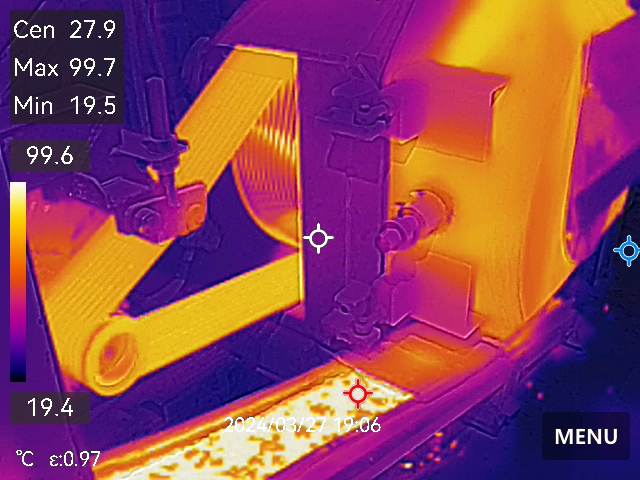

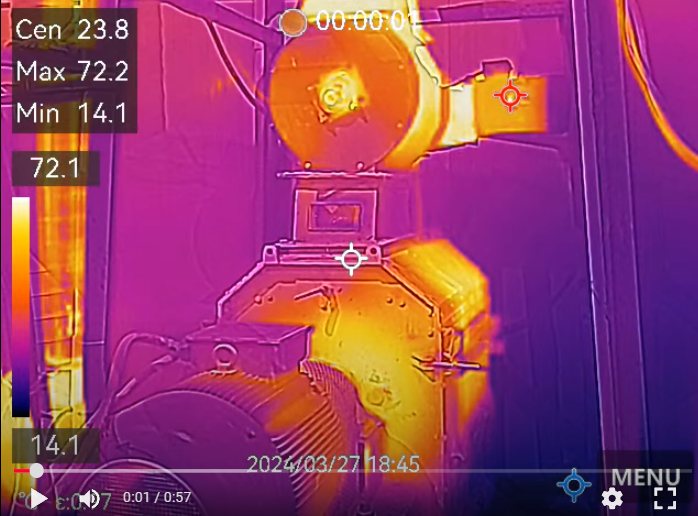

Use of modern thermography

Thermal measurements were carried out to compensate for the lack of technical data. These showed that

- sharp temperature increases on bearings and drives,

- Overload areas on the pellet press,

- inefficient heat conduction in the drying system,

- potential fire risks due to incorrect insulation,

- unevenly utilized components.

The thermal images provided objective information about load conditions that the operator himself was not aware of.

Overall rating

The system was operational, but:

- technically outdated

- Inadequate in terms of safety

- undocumented

- high-maintenance

- Energy inefficient

- with considerable risks for continuous operation

Economic reconstruction in the EU would have been neither approvable nor cost-covering.

Recommendation to the customer

After evaluating all the data, a clear recommendation was made:

Do not buy the system.

This protected the customer from an investment that would later have resulted in high follow-up costs – for conversion, retrofitting, repair and safety measures.

Why this story is important

This project is an example of the added value offered by independent technical due diligence:

- Protection against bad investments

- Objective evaluation instead of sales pitches

- Technical analysis by real experts

- Clear, fact-based basis for decision-making

- Manufacturer independence

- Experience from real plant operations

Customers receive a neutral, honest assessment – free from sales interests.

Conclusion

The combination of mechanical engineering expertise, practical experience and modern diagnostic technology makes it possible to evaluate used systems professionally.

In this case, the decision was clear:

Better not to buy.

A good example of how technical expertise has protected customers from making the wrong decisions and avoided considerable costs.