Industrial pelletizing technology from a single source End-to-end process solutions from size reduction to cooling

Integrated process solutions covering size reduction through to cooling

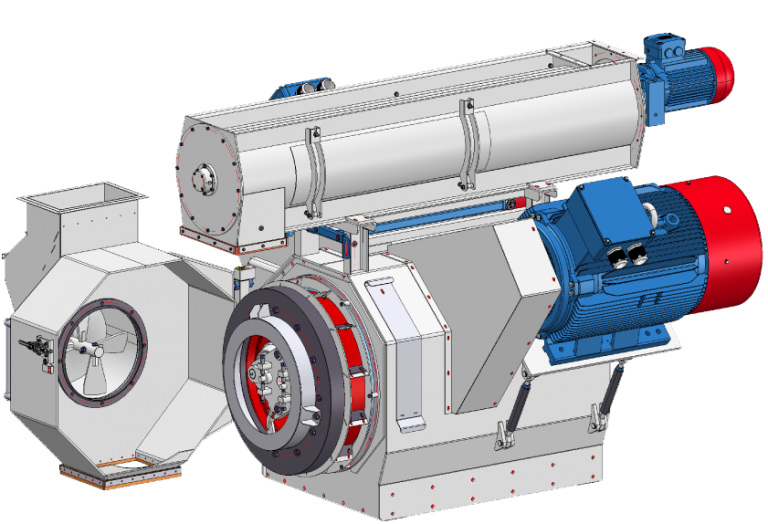

Pellet presses for the compaction of biomass and free-flowing bulk materials.

Industrial design for continuous operation.

Design parameters and performance data are defined according to the specific application.

Short description

Pellet presses are used for the continuous compaction of processed, free-flowing raw materials into dimensionally stable pellets. They represent a central process step in biomass processing and are used in industrial plants for the production of fuels, animal feed, or technical pellets.

The design of the pellet presses is application- and process-specific and covers a wide range of capacities – from compact units to large-scale industrial plants.

Principle

The conditioned raw material is continuously fed into the press chamber of the pellet press. There, it is guided by rotating press rollers against a die and pressed through the die bores under high pressure.

Due to pressure, friction, and temperature, the material undergoes plastic deformation, resulting in the formation of dimensionally stable pellets with defined geometry. The pellet length is adjusted by a downstream knife that cuts the emerging press strands.

The pellets leave the press at elevated temperature and are cooled and further processed in subsequent process steps.

Integration into the process

Pellet presses are typically integrated into the following process chains:

- after the size reduction and screening of the raw material

- after dosing and, if required, conditioning

- before cooling, screening, and conveying equipment

Integration is carried out either as a standalone machine or as part of a fully coordinated pelletizing line. A stable and uniform material feed is crucial for reliable press operation and consistent pellet quality.

Design features

- Robust industrial design for continuous operation

- Press chamber with die and press rollers

- Interchangeable dies for adjusting pellet diameter and geometry

- Adjustable press rollers for optimizing the pressing behavior

- Heavy-duty base frame for absorbing the pressing forces

- Prepared for connection to dosing, cooling, and conveying equipment

- Designed for different raw materials and formulations

Technical specifications (general)

- Operating mode: continuous

- Material feed: metered, external

- Pressing system: die with press rollers

- Pellet diameter: application-dependent

- Pellet length: adjustable

- Drive power: dependent on throughput and material

- Cooling after pressing: required

(All performance, throughput, and quality parameters depend on the raw material and application and are designed on a project-specific basis.)

Benefits

- Reproducible pellet quality

- High dimensional stability of the pellets

- Continuous and process-reliable operation

- Adaptable to different raw materials and formulations

- Robust, long-lasting construction

- Integrable into modular process lines

Pellet presses at a glance

The pellet presses shown below are designed as industrial standalone machines or as part of complete process lines.

They differ in size, drive power, and output capacity and are each adapted on a project-specific basis to the intended raw material, the desired pellet quality, and integration into the overall process.

All press types shown are designed for continuous operation and can be combined with upstream conditioning, dosing, or size reduction units as well as downstream cooling and screening systems.

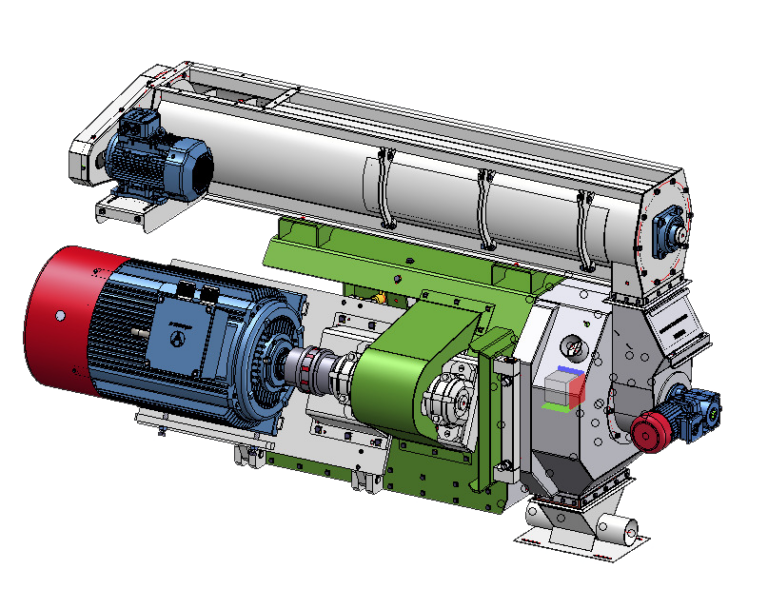

Technical Data

- Die diameter (internal):

270 mm - Working width:

50 mm - Main drive power rating:

22 kW - Conditioner:

2.2 kW - Forced feeder:

0.18 kW - Power transmission:

V-belt (8-groove) - Machine base:

Cast iron - Lubrication system:

Grease / oil - Number of press rollers:

2 pcs - Dimensions:

L 810 × W 1,040 × H 1,716 mm - Total weight:

approx. 1,400 kg - Output capacity:

approx. 150–250 kg/h (wood, guideline value)

Data sheet Pelletmill MP270; Brochure MP. 270_EN. pdf; Brochure MP.270_EN.pdf

Brochure MP.270_RU.pdf; Brochure MP.270_CZ.pdf

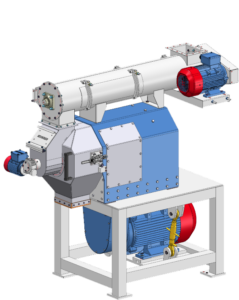

Technical Data

- Die diameter (internal):

400 mm - Working width:

80 mm - Main drive power rating:

75 kW - Conditioner:

3 kW (included) - Forced feeder:

Integrated - Drive type:

V-belt - Number of V-belts:

16 pcs - Machine base:

Cast iron - Magnet in the inlet:

Integrated - Lubrication system:

Grease / oil - Number of press rollers:

2 pcs - Dimensions:

approx. L 2,450 × W 1,800 × H 1,550 mm - Total weight:

approx. 5,000 kg - Output capacity:

approx. 500–700 kg/h (wood, guideline value)

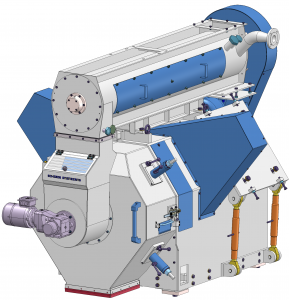

Technical Data

- Die diameter (internal):

510 mm - Working width:

100 mm - Main drive power rating:

110 kW - Number of motors:

1 - Drive type:

V-belt - Number of V-belts:

15 pcs - Forced feeder:

Integrated - Magnet in the inlet:

Integrated - Machine base:

Cast iron - Number of press rollers:

2 pcs - Conditioner:

Integrated

(connected load approx. 3 kW) - Dimensions:

L 1,720 × W 2,960 × H 1,509 mm

(including motors) - Total weight:

approx. 4,300 kg - Output capacity:

approx. 800–1,200 kg/h (wood, guideline value)

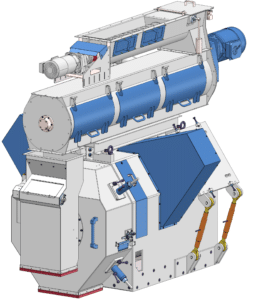

Technical Data

- Die diameter (internal):

520 mm - Working width:

100 mm - Main drive power rating:

2 × 75 kW or 2 × 90 kW - Number of motors:

2 - Drive type:

V-belt - Number of V-belts:

16 pcs - Forced feeder:

Integrated - Magnet in the inlet:

Integrated - Machine base:

Cast iron - Number of press rollers:

2 pcs - Conditioner:

Integrated

(connected load approx. 5 kW) - Dimensions:

L 2,360 × W 2,082 × H 1,827 mm - Total weight:

approx. 8,450 kg - Output capacity:

approx. 1,500–2,300 kg/h (wood, guideline value)

Technical Data

- Die diameter (internal):

660 mm - Working width:

115 mm - Main drive power rating:

2 × 110 kW or 2 × 132 kW - Number of motors:

2 - Drive type:

V-belt - Number of V-belts:

24 pcs - Forced feeder:

Integrated - Magnet in the inlet:

Integrated - Machine base:

Cast iron - Number of press rollers:

2 pcs - Conditioner:

Integrated

(connected load approx. 7.5 kW) - Dimensions:

L 3,550 × W 2,323 × H 2,569 mm - Total weight:

approx. 12,000 kg - Output capacity:

approx. 2,500–3,300 kg/h (wood, guideline value)

Technical Data

- Die diameter (internal):

700 mm - Working width:

105 mm - Main drive power rating:

2 × 132 kW - Number of motors:

2 - Drive type:

V-belt - Number of V-belts:

22 pcs - Forced feeder:

Integrated - Magnet in the inlet:

Integrated - Machine base:

Cast iron - Number of press rollers:

2 pcs - Conditioner:

Integrated

(connected load approx. 11 kW) - Dimensions:

L 2,778 × W 2,509 × H 2,180 mm

(without motors) - Total weight:

approx. 10,200 kg - Output capacity:

approx. 2,800–3,600 kg/h (wood, guideline value)