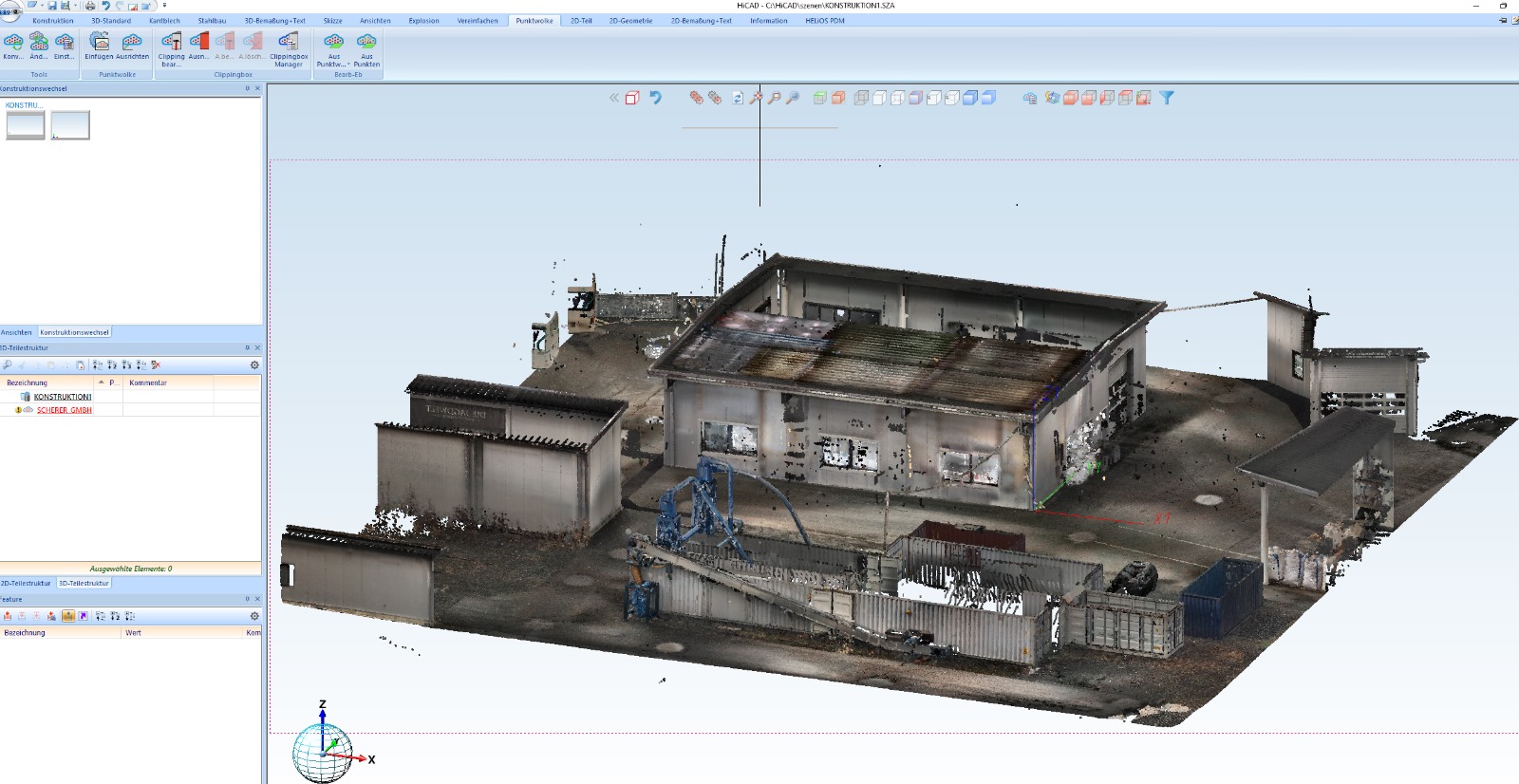

Digital twin of an industrial site – 3D laser scanning for a retrofit project

Initial situation

A reliable digital data basis was to be created for the future expansion and optimization of an existing industrial site. The existing buildings, workshop areas and outdoor areas had grown historically and had been structurally altered in parts. Current technical documentation was no longer available in full.

In order to be able to precisely plan planned conversions, integration of new machines, media routing and logistics routes, the entire site was recorded using modern 3D laser scanning. The aim was to create a digital twin that could serve as an exact basis for retrofit planning and CAD designs.

Acquisition of the point cloud

A complete point cloud was created for the project, which depicts both indoor and outdoor areas.

Among other things, the following were recorded:

- Hall structures

- Building envelope

- Workshop areas

- Machine environments

- Traffic and open spaces

- Access zones, ramps, container spaces

The scan data was then cleansed, registered and exported as a uniform point cloud for further processing.

Integration of the point cloud in HiCAD

The point cloud was imported directly into HiCAD in order to make all relevant areas accessible for the subsequent design. This made it possible to:

- Inventory structures traced to the millimeter,

- Collisions and bottlenecks detected early,

- and planning areas can be precisely defined.

The ability to design machines, steel structures or plant modules directly in the context of the real geometry without having to rely on unreliable measured values or old plans is particularly valuable.

Advantages for retrofit and redesign

Digital recording provides decisive advantages:

- Complete transparency of existing geometries

- Exact distances, heights, roof pitches, plinths and openings

- Ideal basis for CAD-based conversion planning

- Reliable planning of new machines or extensions

- Immediate collision check

- Better coordination of all trades

The exact representation of reality means that decisions can be made faster and more reliably – without recurring on-site measurements.

Application areas of the digital twin

The digital location forms the technical basis for:

- Conversion planning

- Expansion of the production areas

- New installation of machines, containers and infrastructure

- Creation of new media guides

- Steel construction adaptations

- Traffic and logistics optimization

This means that the point cloud not only serves as documentation, but also as an active planning tool for future development steps at the site.

Conclusion

3D laser scanning and the integration of the point cloud in HiCAD created a precise digital twin of the factory premises. This provides the basis for all future retrofit steps – from machine setups to complete conversion concepts.

This method makes the company’s own premises technically penetrable, plannable and sustainable for further development.