Hammer mills for size reduction of biomass and free‑flowing bulk materials. Robust industrial design for continuous operation. Particle size, capacity, and configuration are adapted to the specific application.

Hammer mills for biomass and bulk material applications

Short description

Hammer mills are used for the continuous size reduction of biomass, organic residues, and other free‑flowing bulk materials.

They are employed to produce defined particle sizes for downstream processes such as pelletizing, briquetting, or thermal utilization.

The design is application-specific and covers a wide performance range – from compact units to large-scale industrial systems.

Principle

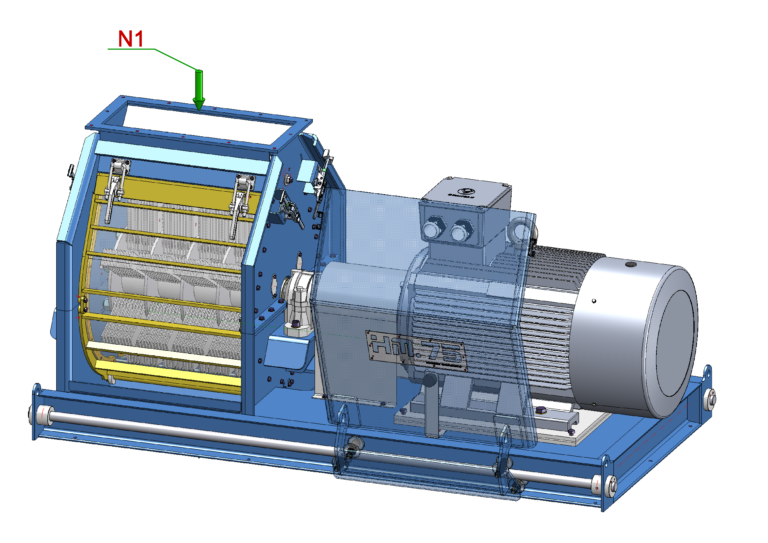

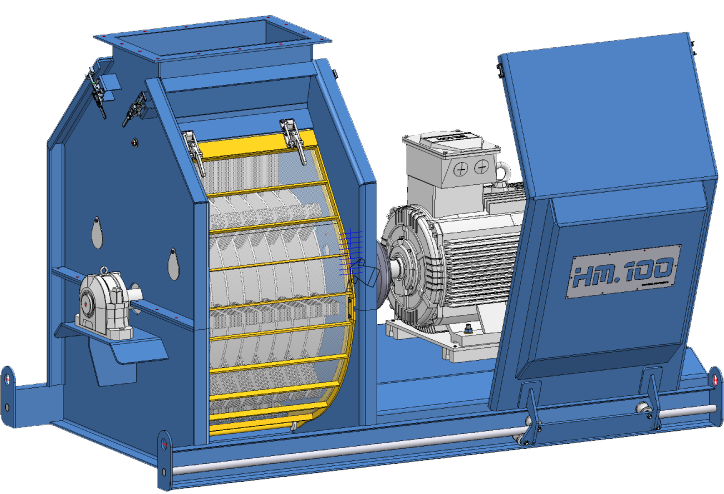

The raw material is fed into the grinding chamber through the material inlet, where it meets a rotating rotor with freely swinging hammers.

The high peripheral speed of the rotor reduces the material and guides it within the grinding chamber.

Classification is achieved via an interchangeable screen that defines the maximum particle size.

Material can only exit the grinding chamber through the discharge once it has reached the specified particle size.

The hammer mills are designed for continuous operation and, depending on material properties, moisture content, and screen configuration, can be used for both coarse and finer size-reduction tasks.

Einbindung in den Prozess

Hammer mills are typically used as a pre- or intermediate stage in process engineering plants, including for:

- Upstream of pellet presses or briquetting systems

- For pre-grinding of biomass

- For homogenization of raw materials

- For adjusting particle size to subsequent process steps

Integration can be as a standalone machine or as part of a complete process line.

Design features

- Robust welded steel construction for continuous industrial operation

- Grinding chamber accessible from both sides for maintenance and service

- Rotor with freely swinging hammers

- Interchangeable screens for adjusting particle size

- Capability for operation with variable rotor rotation direction (depending on configuration)

- Prepared for connection to extraction and dosing systems

- Designed for different materials and moisture ranges

Technical specifications (general)

- Operating mode: continuous

- Material feed: metered, external

- Rotor: dynamically balanced

- Speed: application-dependent

- Screen size: selectable, project-specific

- Drive power: dependent on throughput and material

- Extraction: required, designed according to application

(All power and throughput specifications depend on material and application and are designed on a project-specific basis.)

Benefits

- Reliable size reduction of various materials

- Reproducible particle sizes

- Robust and maintenance-friendly design

- High operational reliability

- Flexible and adaptable to different process requirements

- Suitable for small to large throughput ranges

Hammer mills for size reduction of biomass and free‑flowing bulk materials.

Robust industrial design for continuous operation.

Particle size, capacity, and configuration are adapted to the specific application.