Produkte

Products

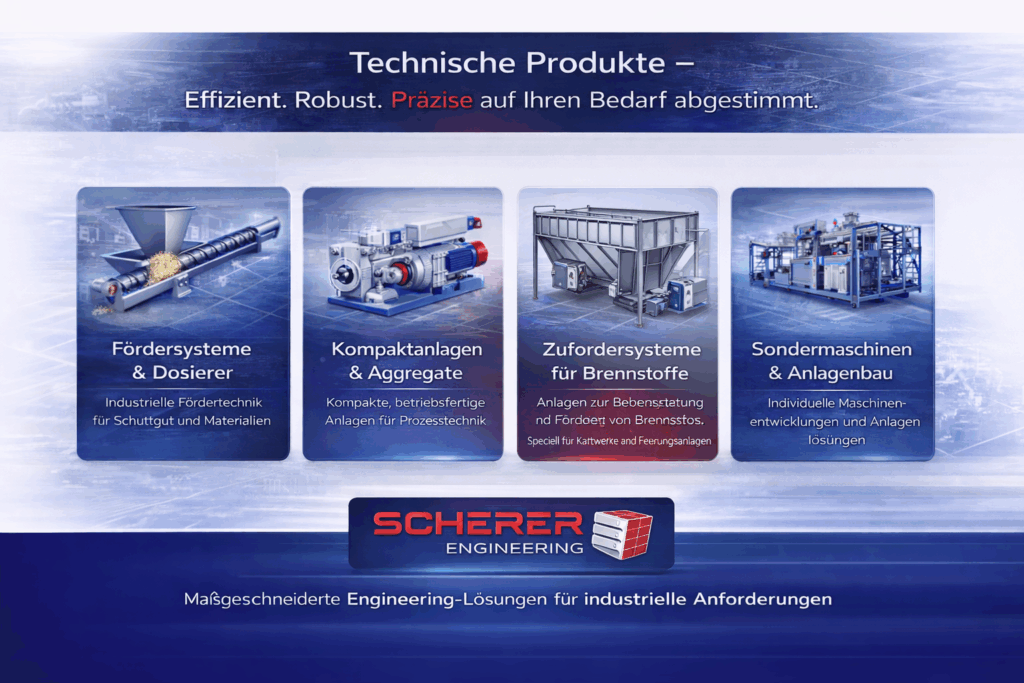

Our products are developed from specific industrial requirements and are consistently designed for function, robustness and practicality. The focus is on feeding, conveyor and plant systems as well as individually developed machine solutions – tailored to the respective process and application.

Unsere Produkte

Our products

Our products are characterized by the highest quality and state-of-the-art manufacturing technology. Of course, we offer you all this at a fair price.

Our many years of experience and special knowledge and talents are reflected in our products.

You as a customer benefit from this, now and in the future!

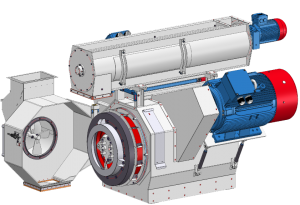

Pellet press MP.270, MP.400, MP.520, MP.660, MP.700

The pellet presses are used to compress biogenic bulk materials into dimensionally stable pellets. They are designed for continuous industrial operation and are adapted to the raw material, throughput and operating conditions on the process side.

Pellet hygienizer Hypertherm 750

The hygienizer is used for the thermal treatment of pellets to ensure hygienic requirements are met. It is particularly relevant where legal requirements or process-related hygiene standards must be met.

Countercurrent cooler GSK.9

Counterflow coolers are used for the controlled cooling of freshly pressed pellets. They stabilize the product mechanically and thermally and are a key component for consistent pellet quality.

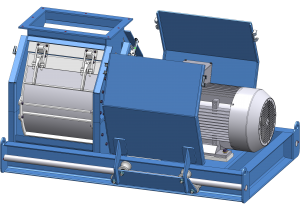

Hammer Mill HM.50; HM.75

Hammer mills are used for crushing and processing raw materials before pelletizing. They enable a defined grain structure and create reproducible conditions for subsequent process steps.

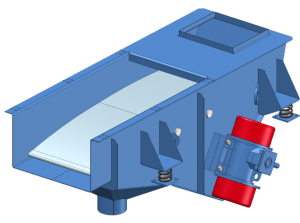

Vibrating sieve SS.5

Vibrating screens are used to classify and separate bulk materials according to grain size. They are used to reliably remove oversize and undersize particles from the process.

Additive doser AD.50

Additive feeders enable the controlled addition of additives to ongoing processes. They contribute to process stability and the targeted influencing of product properties.

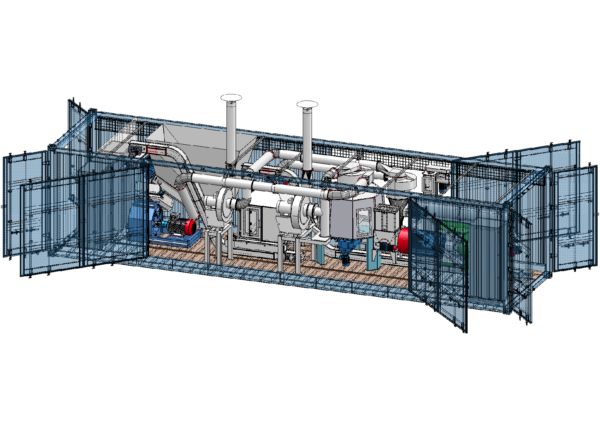

Container pellet plant

Containerized pelleting systems combine several process steps in a compact, modular unit. They are suitable for decentralized applications, pilot plants or temporary production sites.