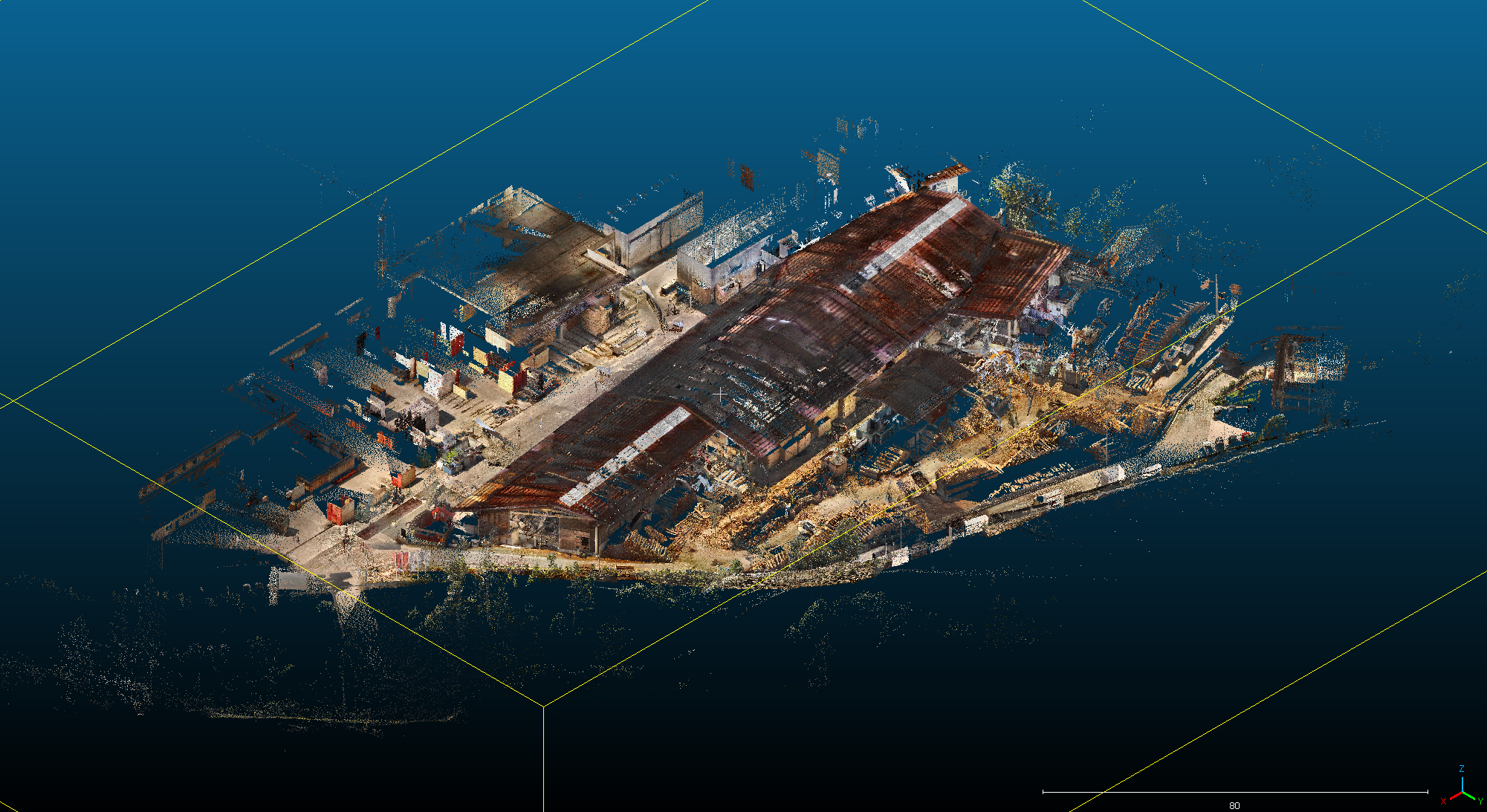

3D laser scanning and CAD reconstruction of a sawmill – digital basis for a retrofit

Initial situation

A reliable digital basis was required for the planning of an extensive retrofit project in an existing sawmill operation. The existing building structures had grown historically and were not available in up-to-date technical documentation.

Precise geometry data was required for conversions, extensions and the integration of new plant technology – particularly in the area of load-bearing structures, roof shapes, traffic areas and machine environments.

Traditional measurement methods are hardly sufficient in such facilities: angled geometries, areas that are difficult to access and large surfaces make manual measurement time-consuming and prone to errors. A complete 3D laser scanning was therefore commissioned, including digital reconstruction of all relevant building elements.

Scope of services

The project comprised several coordinated work steps:

- On-site laser scanning

Implementation within two days.

The data was collected:

- External building envelope

- Roof structures

- Hall areas

- Traffic and storage areas

- statically or functionally relevant interior areas

The scan data was provided as a point cloud in e57 format, supplemented by a viewer for direct visual inspection.

(Details confirmed from the final report

- Data preparation and cleansing

The point cloud was cleaned, filtered and segmented for further processing. Basis for subsequent modeling.

- CAD reconstruction in HiCAD/HELiOS

- Basic building structure

- Roofscapes

- Concrete and plinth areas

- Relevant system proximity geometries

- Intersections, reference planes and planning axes

The modeling was carried out precisely on the basis of the scan data, including iterative coordination with the client’s project team.

- Data exchange and project integration

The collaboration took place via a shared cloud folder.

Transmitted were:

- STEP files

- PDF views

- Updated designs according to change requests

- Additional screenshots and evaluations

The feedback loops consisted of written markers, telephone discussions and online meetings, which meant that changes could be implemented promptly.

- Final result

Was provided:

- a fully usable STEP file (~182 MB)

- finished point clouds

- Viewer data

- Structured documentation

This file forms the basis for the planning of the conversions, the connecting constructions and the subsequent system integration.

Special challenges

- Large, complex building structures

- Different ceiling and roof heights

- Angled areas with limited accessibility

- No current inventory documentation available

- Necessary millimeter-precise basis for subsequent steel construction and system designs

Thanks to the use of 3D scanning, the entire plant could be completely digitized without significantly affecting operational processes.

Project benefits for the customer

- Precise geometry data as a reliable basis for planning

- Significant time savings compared to manual measurement methods

- Risk minimized through planning based on reliable actual data

- Direct reusability in CAD, 3D design and BIM

- Complete digital documentation for future projects

Conclusion

The combination of modern laser scanning, professional data processing and precise 3D reconstruction created a reliable digital basis for a large-scale retrofit project in the sawmill environment. The data provided enables exact planning reliability, simplifies the coordination of subsequent trades and accelerates all further design steps.

This not only documents the sawmill – it also makes it fit for the future.