MP510 - quiet, controlled, powerful

The pellet press that was created because standard solutions had reached their limits.

Why does this press exist?

The MP510 was developed based on real operating experience. Many operators reported the same difficulties with existing presses: starting problems under product, overloaded motor bearings, vibrations, high wear and space problems in container systems. The question was not whether to build another press – but whether a better one could be built that would solve these problems permanently.

What was technically difficult?

The technical challenge was to combine high performance, quietness and a compact design. To achieve this, proven principles had to be critically questioned and recombined: a powerful 8-pole motor, a relieved drive train and a design layout that focuses on maintenance and stability. The result is a machine that works reliably exactly where others reach their limits.

When classic pellet mills reach their limits.

Many operators struggle with similar problems with conventional presses:

- Shaft and bearing breakages

- high belt slip

- strong vibrations

- unreliable starts under product

- Difficult maintenance

- Designs too large for compact system layouts

- Above-average number of fault triggers

The MP510 was developed to eliminate precisely these weaknesses.

Developed from real operating experience

A systematic analysis was carried out in close cooperation with the technical manager of a plant operator:

- What works well?

- What causes problems?

- Which features are really necessary?

Several development cycles resulted in a concept that is more powerful, more compact and more reliable than conventional solutions in this performance class.

Construction time: approx. 2 months

Commissioning: 1 week – stable operation immediately

The technical core ideas of the MP510

8-pole high-torque motor

- Safe start under product

- Larger driving pulley possible

- Minimal slip, less preload

- Smooth machine operation

Ultra-compact design

- container-capable

- Very good accessibility

- Small space requirement despite 110 kW output

The advantages in daily operation

Bullet list:

- Safe start under load

- Very few fault triggers

- Low-vibration, controlled machine operation

- High-quality wear materials

- Easy access to all maintenance-relevant areas

- Perfect suitability for container systems

Technical data (extract)

Parameters | Value |

Connected load | 110 kW, 8-pole |

Wood throughput | 1200-2000 kg/h |

Working width | 138 mm |

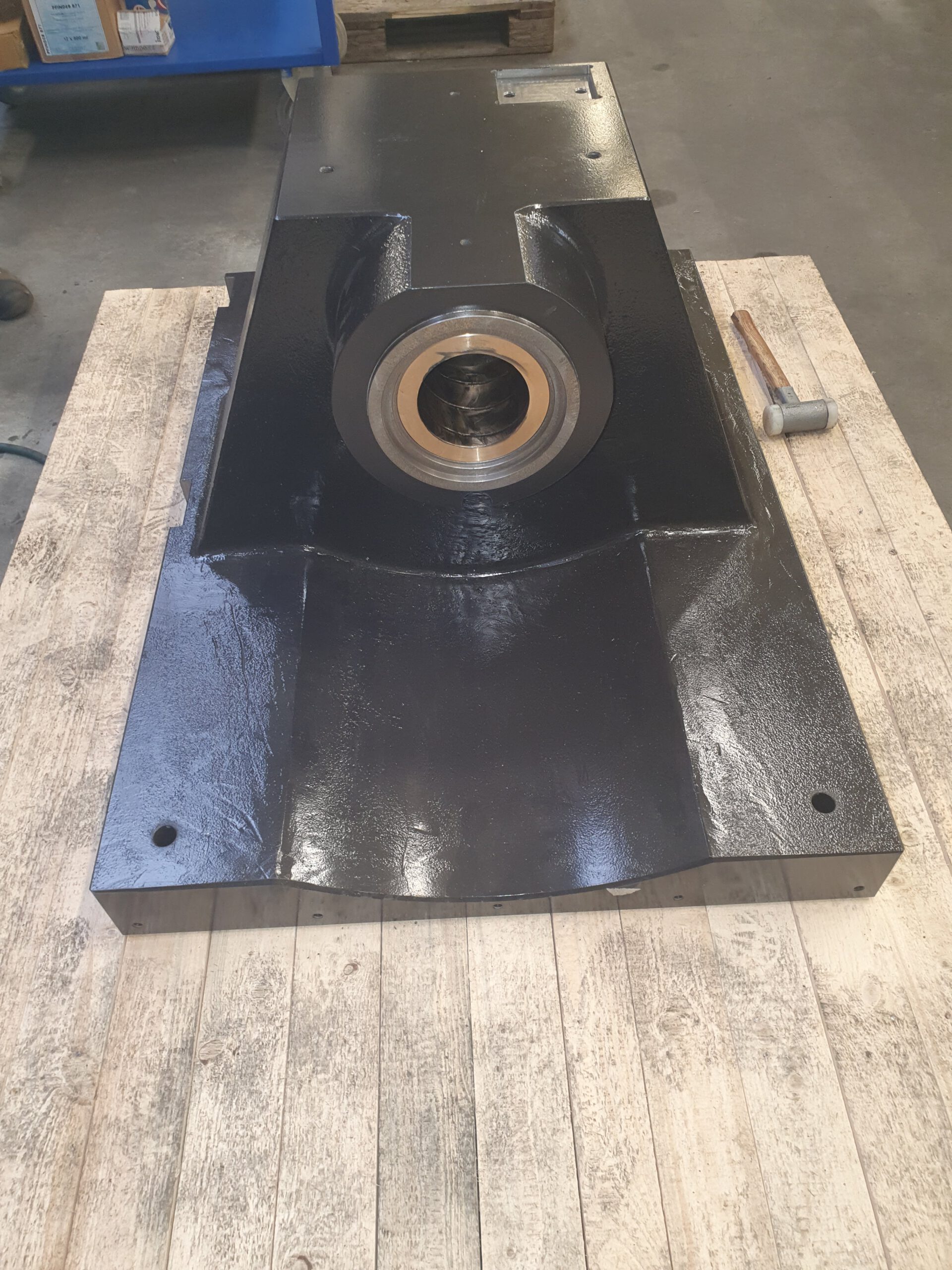

Die | Ø 510 mm inside |

Drive | 12-fold V-belt, countershaft |

Forced feeder | 0.18 kW |

Conditioner | 3 kW |

Dimensions | 2960 × 1720 × 1509 mm |

Weight | approx. 4,290 kg |

A machine that was developed out of problems.

The MP510 is not a series product.

It is a technical answer to real challenges – compact, robust and reliable.

It combines the experience of over 20 years of pelleting with a clear focus on reliability and user-friendliness.