Research & Development – Technology begins where routine ends.

Engineering – Development – Solutions (R&D)

Scherer Engineering develops machines, components and process modules where the conventional market does not offer suitable solutions. Our work always begins when standard technology reaches its limits or does not exist.

We are a technically oriented development company specializing in mechanical and plant engineering:

- Prototype development

- Experimental process engineering

- Mechanical and fluidic optimization

- Modernization and re-engineering of existing systems

- Development of new units and functional modules

- Test operation & validation

Our projects are developed in close cooperation with industrial partners from the wood-based materials, biomass, recycling and special machine construction sectors. We combine practical experience with modern design, 3D laser scanning, digital modeling and systematic testing

Why Research & Development?

Many industrial tasks cannot be solved with “off-the-shelf” machines. Materials behave differently, processes are complex and every system has individual requirements. Our task is to develop further where there are no suitable series solutions.

We conduct research & development because:

- Standard machines are often not sufficient

- Material behavior is not exactly predictable

- Processes need to be optimized, adapted or rethought

- prototypes are necessary to solve technical uncertainties

- Companies need solutions that work, not compromises

Our R&D work is based on:

- technical analysis

- Construction & Modeling

- Prototype construction

- Experimental farms

- Optimization & validation

This results in solutions that did not previously exist on the market.

What we develop

Our development projects operate in areas where material, mechanics or flow reach their limits:

- Special machines and innovative process modules

- Fluid mechanical solutions for lightweight materials and fiber flows

- Design of highly stressed mechanical components

- Test systems, functional models and test modules

- Development of new material routes and process chains

- Variant comparisons, test series, systematic optimization

- Sophisticated transfer points, shredding technology and conveyor mechanisms

All of this is not based on routine – but on actual technical development work.

How we work

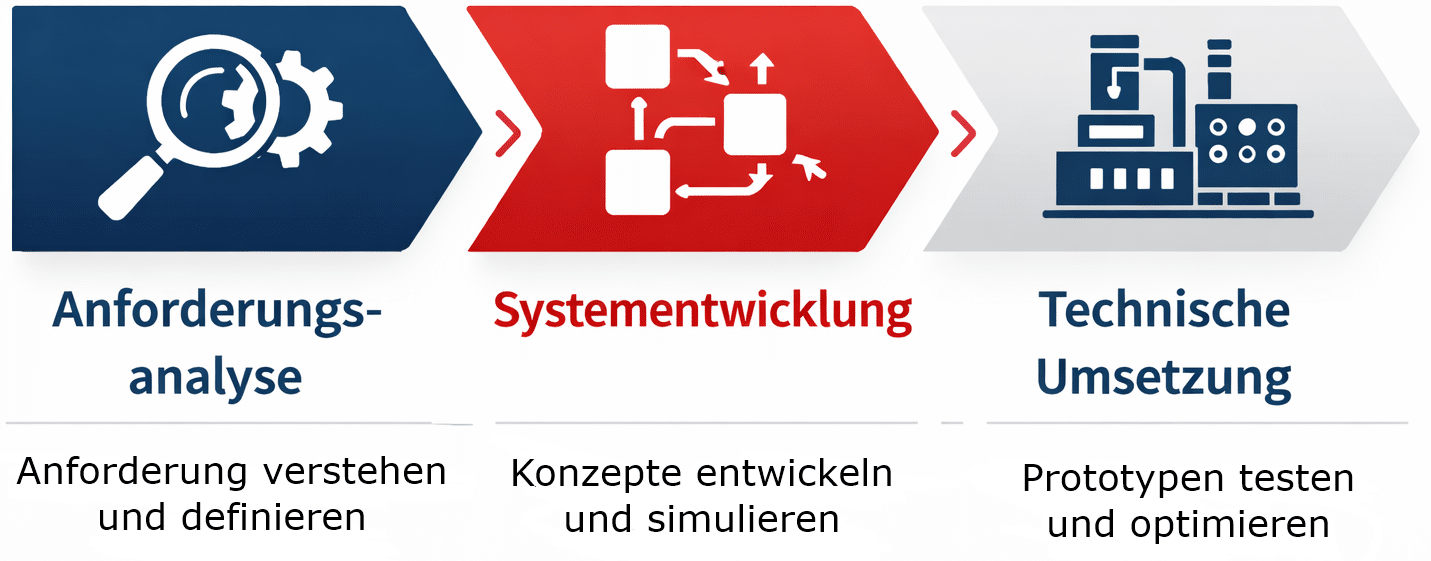

Our methodology is practical, data-based and consistently iterative:

- Analysis of the technical challenge

We identify what is unpredictable – material behavior, flows, load paths, process dynamics. - Variant creation & concept development

Several solutions are often developed in parallel. - Construction & design

Development of new geometries, modules, mechanics and flow-guiding components in HiCAD/HELiOS. - Prototypes & test units

We test ideas in real life, not just in theory. - Test operation & measurements

Parameters, forces, flow rates, flows, material behavior – we measure what actually happens. - Iteration, adaptation, validation

A solution is created from several variants.

The solution becomes a resilient module.

The module becomes an industrially deployable system.

Why our customers commission us

Companies come to us when they reach their technical limits:

- if an aggregate, a machine or a process does not exist

- when something should theoretically work, but practically does not

- if material, moisture, density, shape or flow cannot be controlled

- if existing technology fails or is not stable enough

- when a process needs to be completely rethought

- if a prototype or test system is required that is not available for purchase

We take on precisely these types of projects – and bring them to a functioning solution.

Special strengths

- in-depth mechanical design experience

- Very strong material, fiber and flow technology expertise

- Fast prototype & test cycles

- Reliable, reproducible documentation

- Integration into existing industrial plants

- Development in a confined space, under real boundary conditions

- Technical solutions that are not “nice to have” but functionally decisive

Our developments are not based on assumptions.

They are based on real measurement data, test results and reliable designs.

Documentation & engineering standard

Every development is documented in a fully traceable manner:

- HELiOS PDM system

- Versioned CAD models

- constructive variants

- Test and measurement protocols

- Pictures, videos, parameter series

- Technical analyses and observations

This creates a development process that is testable, reproducible and usable in the long term.

Our claim

We develop solutions that did not exist before.

We close technical gaps.

We make processes possible that would otherwise not work.

Scherer Engineering – Research & development with substance.