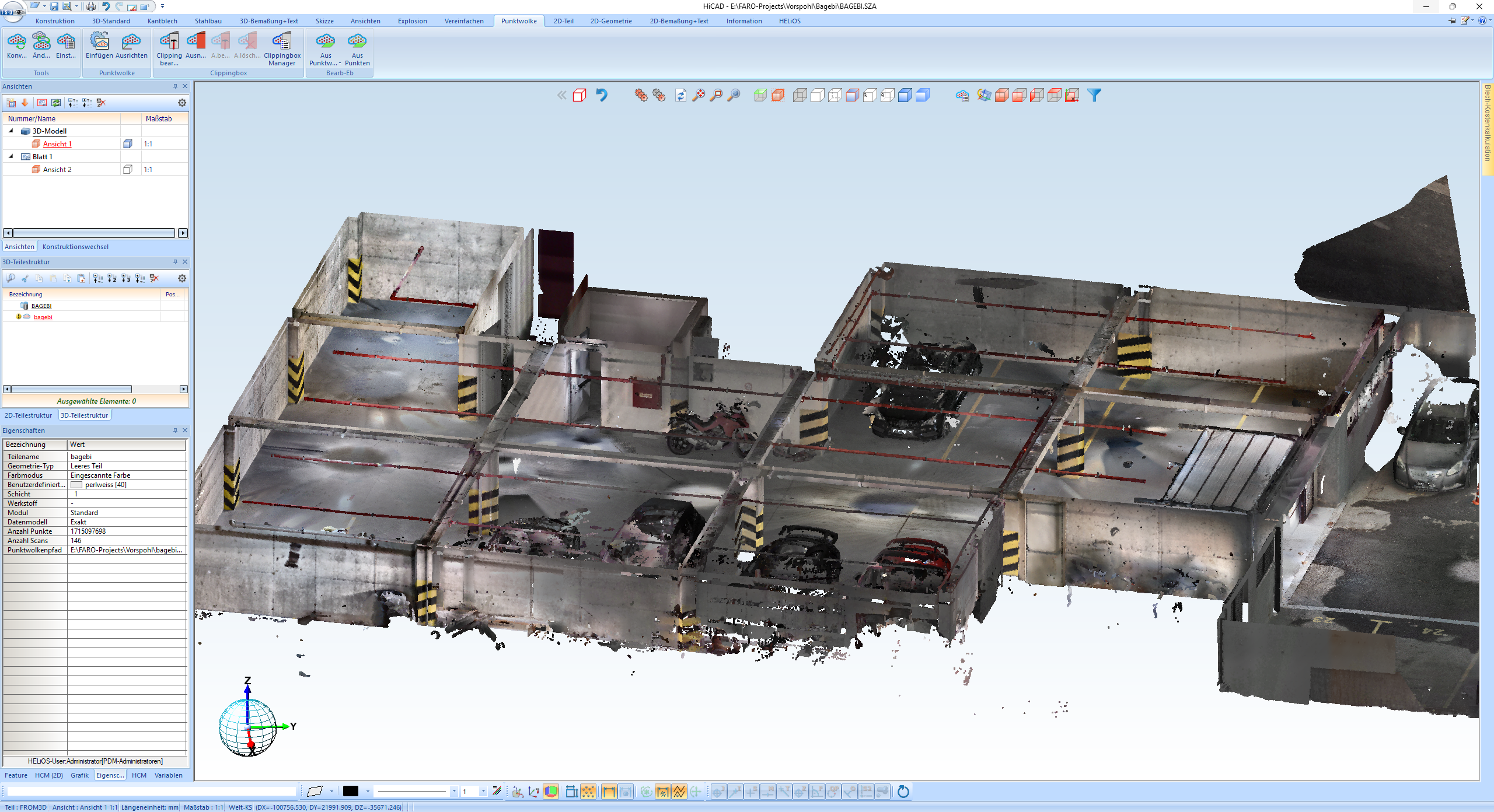

3D laser scanning of an underground parking garage – digital inventory for precise planning

Project overview

For an international customer in Tbilisi (Georgia), a multi-part underground parking garage was completely recorded using 3D laser scanning. The aim was to create a reliable digital basis for planned additional installations and structural adjustments.

The point cloud depicts all relevant components, structures and fixtures with a high degree of accuracy and enables efficient further processing in the CAD system.

Why this project was challenging

Underground car parks are considered challenging scanning environments due to their complex geometries and changing lighting conditions. Added to this:

- Many interfering objects and vehicles in the room

- Changing surfaces (concrete, metal, glass)

- Areas that are difficult to access

- Precise detection of installations in the ceiling and wall area

- Geometric precision for subsequent designs

Despite these conditions, a precise point cloud was created, which serves as a complete digital as-built survey and was imported directly into HiCAD for further processing.

Internationality and interdisciplinarity

The project combines modern plant construction, digitalization and international engineering.

Special features:

- On-site implementation in Georgia

- Data acquisition using a FARO laser scanner

- Further processing and modeling in Austria

- Digital collaboration across multiple countries

- Use of the point cloud as a planning basis for subsequent installations and constructions

This creates an efficient workflow across borders – ideal for retrofit projects where precise inventory data is essential.

Technical result

A complete point cloud was generated from the scan, which accurately depicts the following areas, among others:

- Parking space structure and room layout

- Pillars, walls, ceilings and beams

- Ramps, transitions, height gradations

- Installations and technical infrastructure

- Obstacles and fixtures

- Existing vehicles and temporary objects (for orientation)

The point cloud then served as the basis for:

- Collision-free planning of new constructions

- Precise installation planning

- Geometrically reliable design of supplementary fixtures

- Reduction of planning errors and construction time risks

Conclusion

The project is an example of how 3D laser scanning and modern CAD integration can revolutionize the classic engineering process.

The high-precision digitized environment creates a planning reliability that is indispensable for retrofit projects in existing buildings – across national borders.