Hydraulic chain‑floor system for biomass & bulk materials

Robust discharge solutions for receiving bunkers, silos, and storage bins

Hydraulic chain‑floor systems are a proven solution for the safe and uniform discharge of biomass, wood chips, and other difficult-flowing bulk materials. Conventional discharge systems quickly reach their limits, especially in large receiving bunkers, storage bins, or deep installations. The hydraulic chain floor operates actively and controllably – independent of material moisture, inhomogeneity, or bridging.

Scherer Engineering designs, engineers, and implements hydraulic chain‑floor systems as customized system solutions – precisely adapted to material properties, bunker geometry, and downstream conveying equipment.

Operating principle of the hydraulic chain‑floor system

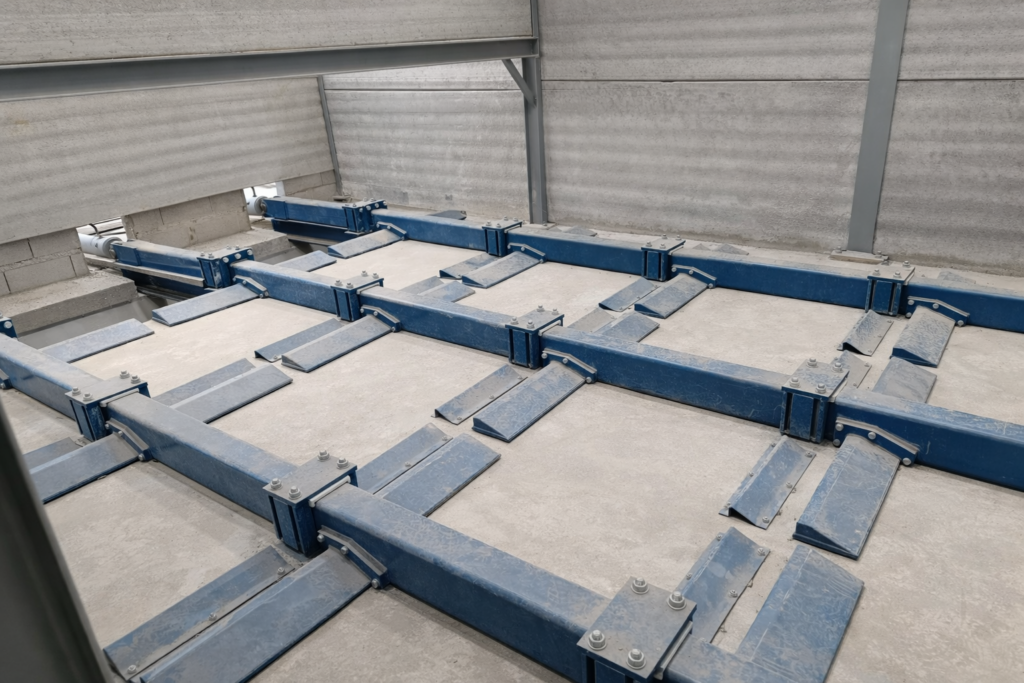

The chain floor consists of several parallel push frames that are cyclically moved by hydraulic cylinders.

Through defined lifting motions, the material is gradually transported toward the discharge point.

The movement is controlled and reproducible, ensuring a consistent material flow.

The hydraulics allow for high forces while maintaining smooth operation.

This makes the system suitable even for wet, compacted, or inhomogeneous biomass with high resistance.

The timing and stroke sequence are designed to achieve a stable discharge rate without tearing the material or releasing it abruptly.

System layout and components

The hydraulic chain‑floor system is modular in design and essentially consists of the following components:

- Chain‑floor / push‑frame construction

Robust, welded steel frames designed for high continuous loads and long service life. - Sliding and guide elements

Defined bearing surfaces for controlled force transmission and minimized wear. - Hydraulic drive

High-performance hydraulic cylinders with coordinated stroke and operating pressure. - Hydraulic unit

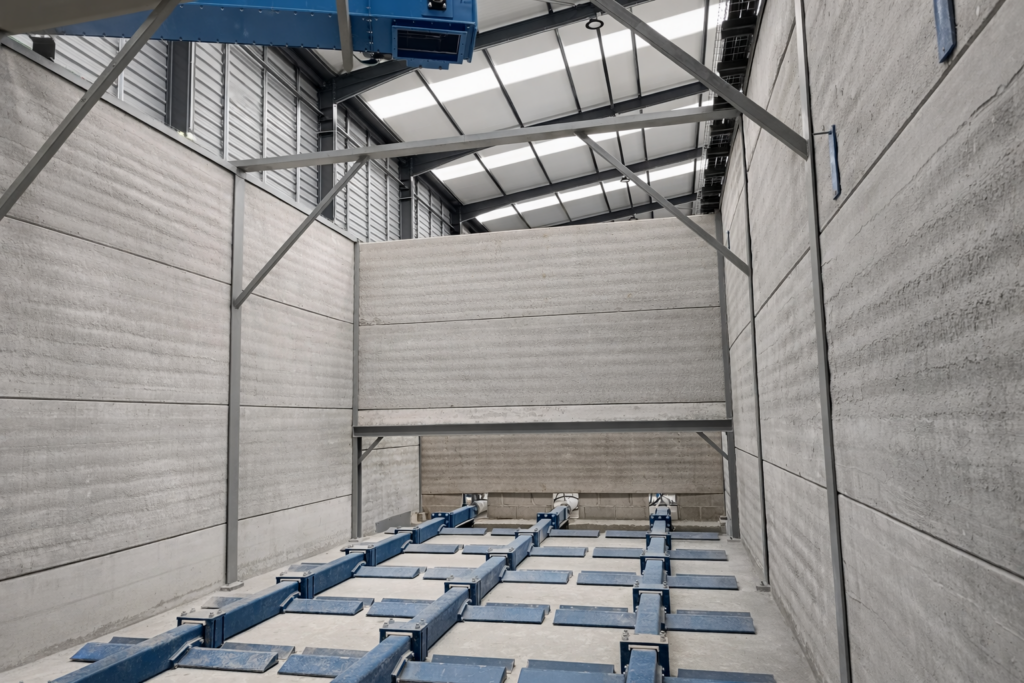

Central unit supplying the cylinders, integrated or externally positioned depending on the project. - Substructure & integration

Designed for installation in concrete bunkers or steel structures, adjustable and assembly-friendly. - Control & automation

Stroke sequence, cycle times, and interlocks are adapted to the process and safely monitored.

Technical design (example system)

The design of a chain‑floor system is project-specific. The following data show a realized reference configuration:

- System dimensions:

Length 12,400 mm, Width 4,850 mm, Overall height 1,000 mm - Stroke of push frames: 800 mm

- Drive: hydraulic

- Maximum operating pressure: 200 bar

- Hydraulic cylinders:

Differential cylinders, cylinder diameter approx. 160 mm - Number of chain‑floor units: 3

- Hydraulic unit: 30 kW

- Suitable for material moisture up to 70 %

- Discharge capacity: approx. 5–10 t/h, depending on material and process conditions

These technical parameters are precisely adapted to the specific application during project planning.

Advantages of the hydraulic chain‑floor system

- Uniform, controlled discharge

- High operational reliability, even with challenging materials

- Reduced downtime

- High mechanical robustness

- Maintenance-friendly design

- Scalable in length, width, and capacity

- Precise adaptation to process and material

Installation and integration into existing plants

Hydraulic chain‑floor systems can be integrated into both new and existing plants. Typical areas of application include:

- Receiving bunkers for biomass

- Storage bins and intermediate storage

- Low‑height silos

- Discharge systems upstream of conveyors, screw feeders, or dosing systems

Thanks to the low overall height and modular design, adaptation to existing concrete or steel structures is usually straightforward.

Project workflow at Scherer Engineering

- Analysis of material, process, and as‑built conditions

- Technical design and layout planning

- Design and fabrication of the chain‑floor system

- On‑site assembly and commissioning

- Handover including technical documentation

Inquiry & Contact

Are you planning a receiving bunker or looking for a reliable discharge solution for biomass or bulk materials?

We are happy to assist you with the design of a hydraulic chain‑floor system – from the initial concept to fully operational implementation.

Contact us for a technical consultation or a project-specific design.

Die hydraulische Zugbodenanlage entstand aus einer konkreten betrieblichen Problemstellung in einer bestehenden Biomasseanlage.

Ziel war es, eine zuverlässige und gleichmäßige Austragung auch bei anspruchsvollen Materialeigenschaften sicherzustellen und gleichzeitig die bestehende Bunkergeometrie weiter zu nutzen.

Die Entwicklung der Zugbodenlösung, die konstruktiven Entscheidungen sowie die Umsetzung vom Bestand bis zur betriebsbereiten Anlage wurden in einem begleitenden Projektbericht dokumentiert.