Additive dosing systems for volumetric dosing of aggregates and binders.

Robust stainless-steel design for continuous operation.

System layout and conveying capacity are application-specific.

Technical data (key specifications)

Connected load:

0.12 kW

Throughput:

0–50 kg/h

Dosing principle:

Volumetric screw feeder

Material properties:

Powdered and granular additives

Operating mode:

Continuous

Material (product-contact parts):

Stainless steel

Integration:

Connection to a higher-level process control system

Weight:

approx. 160 kg

Short description

Additive dosing systems are used for the controlled and continuous addition of aggregates and additives in industrial process lines. They are particularly employed in the wood, biomass, and pelletizing industries to introduce binders, powders, or granulates into the process in a defined and reproducible manner.

Dosing is carried out volumetrically and is adjusted on the process side to the main mass flow. The systems are designed for continuous operation and can be flexibly integrated into existing plants.

Principle

The additive is fed manually or automatically into the dosing system’s storage hopper. From there, it is conveyed to the actual dosing unit, where it is continuously discharged via a screw feeder.

To ensure a uniform material flow, the dosing unit is equipped with an integrated mixing or agitation device that reliably prevents bridging and blockages.

Dosing is performed volumetrically and is typically controlled proportionally to the mass flow of the main process (e.g. dosing screw or press operation). The control system is integrated into the higher-level process control system.

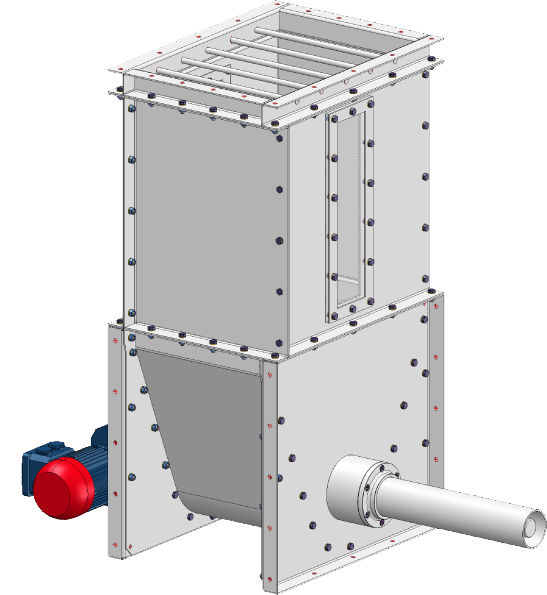

Design and components

An additive dosing system typically consists of the following assemblies:

Lower section (dosing unit)

Dosing screw with integrated mixing or agitation device

Removable components for maintenance, cleaning, and serviceMittelteil (Vorratsbehälter)

Rohstoffvorlage für Dosiergüter

Sicht- und Serviceöffnungen zur FüllstandskontrolleUpper section (filling and access protection)

Protective grid for manual filling

Designed for safe emptying of bagged material

Prevents access to the dosing area during operation

Process integration

Additive dosing systems are typically used:

- for binder addition in pelletizing and briquetting plants

- for dosing aggregates in biomass processes

- for precise recipe and quality control

Integration typically takes place downstream of raw material preparation and upstream of the pellet press or mixing stage. Synchronous control with the main process is essential to ensure consistent product quality.

Design features

- Robust industrial design for continuous operation

- Volumetric dosing via screw feeder

- Integrated mixing and agitation unit

- Maintenance- and service-friendly design

- Modular design for different volumes and conveying capacities

- Completely stainless-steel construction, corrosion-resistant

- Prepared for integration into existing process control systems

Technical specifications (general)

- Operating mode: continuous

- Dosing principle: volumetric

- Material feeding: manual or automated

- Throughput: application-dependent

- Drive power: dependent on dosing rate and material**

- Control system: provided by others / integrated into the process control system**

(All performance and conveying data are designed on an application- and project-specific basis.)

Benefits

- Uniform and reproducible additive dosing

- Reliable material flow without bridging

- Easy integration into existing plants

- Maintenance-friendly design

- Robust design for industrial environments

- Flexibly adaptable to different aggregates