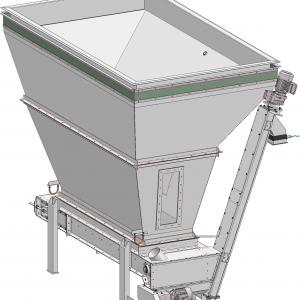

Knick conveyor with tank chain

Description

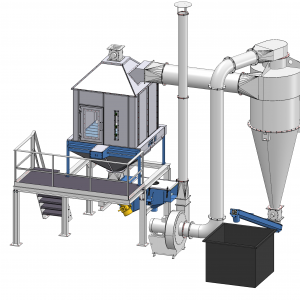

Knick trough chain conveyor with central tank chain is also suitable for heavy applications such as the conveying of wet or dry wood chips!

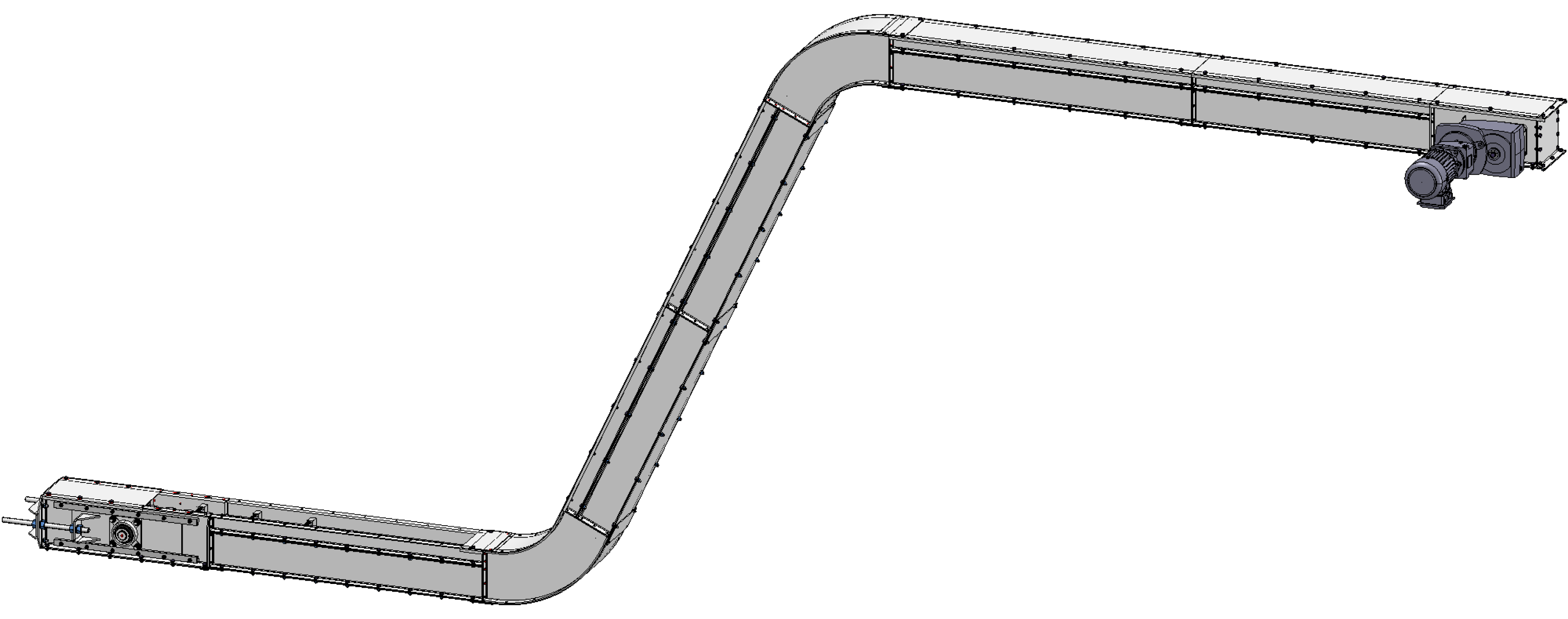

Realize 2 direction changes with only one conveyor where usually at least 2 or even 3 conventional conveyor elements, such as conveyor belt, screw, TKF, elevator etc. are used!

Stainless steel trough chain conveyors for bulk material conveying even in confined spaces.

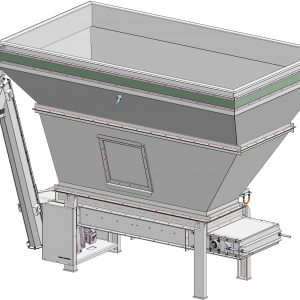

The task area is arranged horizontally. The conveying medium is abandoned here in a controlled manner.

The subsequent deflection station changes the direction of conveying at an angle of 65° and transports the bulk material to the desired discharge height.

A second deflection station changes the conveying direction back to a horizontal conveying system, thus enabling arbitrary drop points.

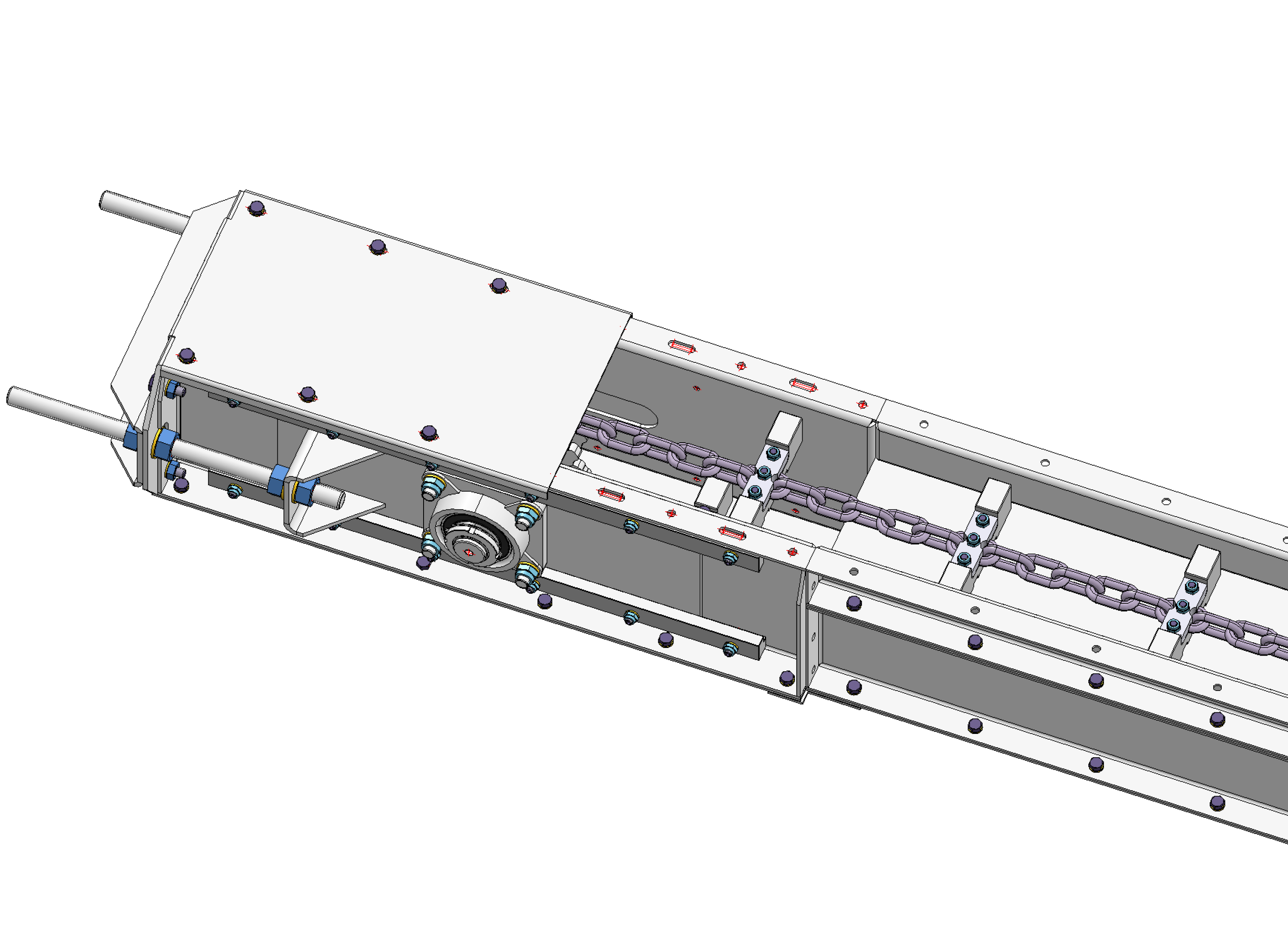

A forged, highly wear-resistant round steel link chain is used here, as it is also used in mining.

This design has the following advantages:

- no clamping of the chain links as with a conventional flange chain (cleavers become difficult to handle over time)

- Operation possible under severe operating conditions

- Moisture insensitive – disadvantage of the tab chain: fit grate in the articulated bolts

- highly wear-resistant sprockets in form-fitting segment design.

Disassembly is possible without disassembly of the drive or deflection station! - Chain runs freely, no housing contact, therefore no wear on housing components by chain

- Co-driver screwed out of PA6. Replacement at any point in mounted condition possible

Funding rates and execution depend on the application and are always matched to the specific application!

Price on request!

Delivery time approx. 8 weeks

Reviews

There are no reviews yet.